-

商品資訊

### Flue Gas Desulfurization (FGD) Explanation

Flue Gas Desulfurization (FGD) is a technology used to remove sulfur compounds (primarily sulfur dioxide, SO₂) from exhaust flue gases resulting from the combustion process. This method is commonly applied in coal and heavy oil power plants or other industrial facilities to reduce air pollution and prevent acid rain. FGD can be achieved through several techniques, with the most common being:

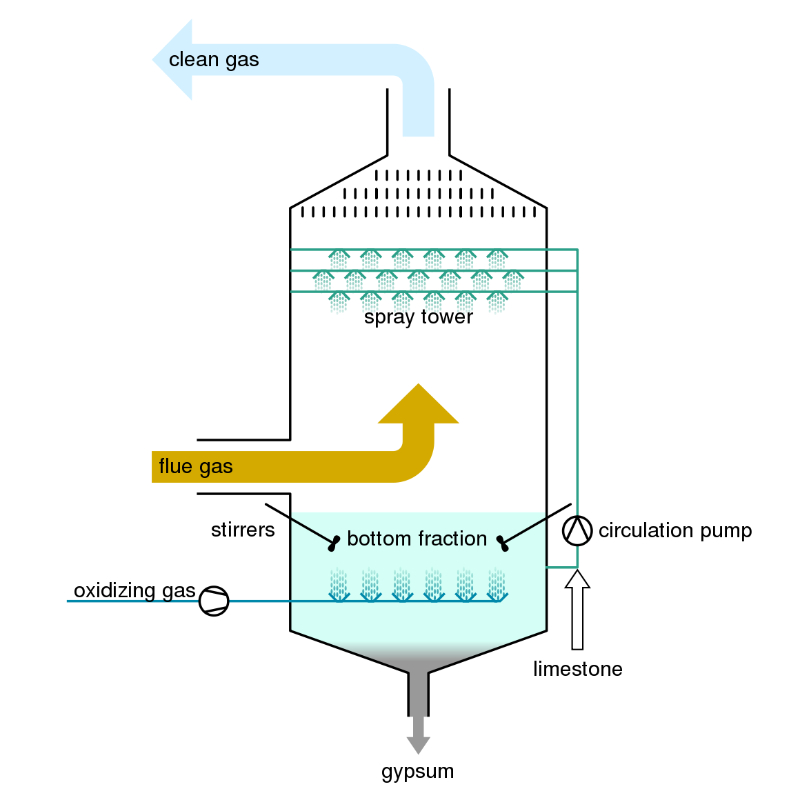

1. **Wet Scrubbing**: This is the most widely used desulfurization method. It involves using an absorbent (usually limestone or lime) to react with the sulfur dioxide in the flue gas, producing sulfates that can be removed from the exhaust. This process typically generates by-products like gypsum, which can be used in building materials.

2. **Dry Scrubbing**: In this method, a dry absorbent (such as lime or calcium carbonate) is used to remove sulfur dioxide. This method is suitable for smaller facilities because its equipment and operating costs are generally lower than those of wet scrubbing.

3. **Semi-Dry Scrubbing**: This method combines elements of both wet and dry scrubbing. It uses lime slurry to treat the flue gas, producing a dry powder as a by-product.

4. **Regenerative Scrubbing**: This method uses a regenerative absorbent to remove sulfur dioxide. The absorbent can be regenerated and reused, reducing consumption and waste generation.

FGD technology plays a critical role in reducing air pollution and protecting the environment, particularly in regions where coal and heavy oil are the primary energy sources. However, these technologies also increase electricity generation costs and fuel consumption due to the additional equipment and energy required to operate the desulfurization systems.

### Emphasis on Semi-Dry Flue Gas Desulfurization

Semi-Dry Flue Gas Desulfurization is one of the most commonly used methods for reducing sulfur dioxide (SO₂) emissions from flue gases. This method combines certain aspects of both wet and dry scrubbing techniques. The main process is as follows:

1. **Absorbent Injection**: In a semi-dry FGD system, the absorbent typically used is lime (Ca(OH)₂) in a water suspension. This suspension is sprayed into the flue gas stream. Upon contact with the flue gas, the absorbent reacts with sulfur dioxide.

2. **Chemical Reaction**: When the lime in the suspension comes into contact with sulfur dioxide, a chemical reaction occurs, forming harmless calcium sulfate (CaSO₄) powder. This process also produces water vapor.

3. **Drying and Particle Formation**: Due to the high temperature of the flue gas, the injected suspension quickly evaporates, drying the calcium sulfate powder produced during the reaction. These dry particles can then be separated from the flue gas.

4. **Particle Removal**: The dried particles are removed from the flue gas using electrostatic precipitators or baghouse filters. The collected particles can be further processed or disposed of as an industrial by-product.

The advantages of semi-dry FGD include:

- **Lower Water Consumption**: Semi-dry FGD uses less water compared to wet scrubbing.

- **Simplified Waste Handling**: The dry powder produced is easier to handle and can be used in some industrial applications.

- **Energy Efficiency**: Since large amounts of water do not need to be evaporated, energy consumption is relatively lower.

However, semi-dry FGD has some limitations, such as potentially lower desulfurization efficiency compared to wet scrubbing and higher requirements for corrosion-resistant equipment. Additionally, this technique may be less effective in treating flue

-

商品Q&A