-

商品資訊

Plastic Raschig Ring Description

Plastic Raschig Rings are a type of tower packing widely used in packed columns for gas-liquid contact processes, such as gas absorption, distillation, degassing, and other chemical unit operations. Due to their simple structure, light weight, corrosion resistance, and high strength, plastic Raschig rings are extensively applied in industries such as petrochemicals, environmental equipment, pharmaceuticals, food processing, and more.

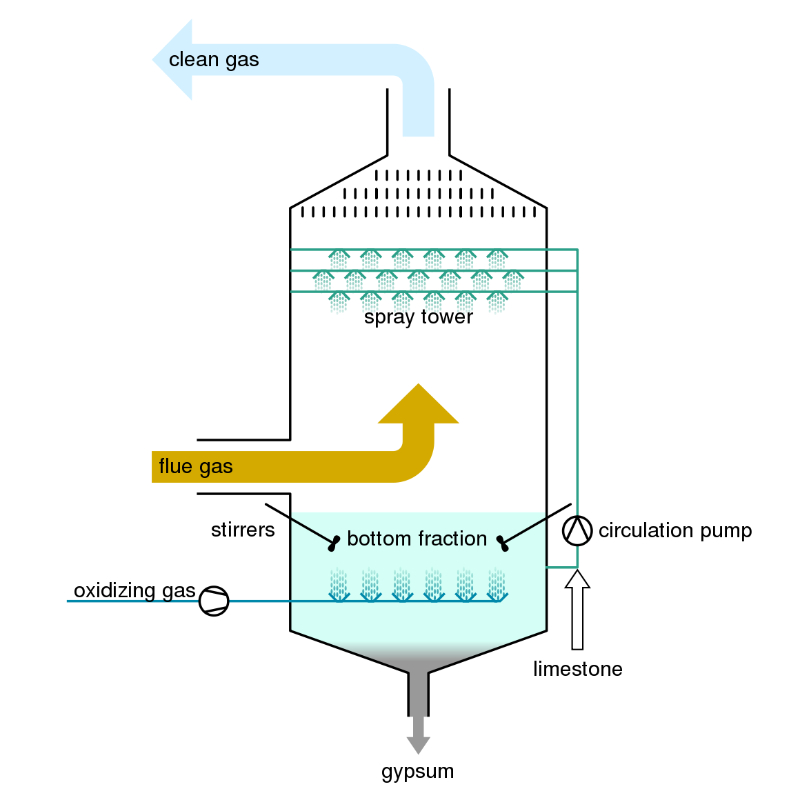

1. Working Principle

The primary function of plastic Raschig rings is to provide surface area for gas and liquid contact, enhancing the gas-liquid exchange process. As gas and liquid flow through the packed column, the surface of the plastic Raschig rings allows for sufficient contact between the two phases, thereby promoting mass transfer (such as gas absorption, distillation, etc.). These rings have a large specific surface area and excellent fluid dynamics, which effectively reduce pressure and improve mass transfer efficiency.

2. Key Features

- Strong Corrosion Resistance: Made from chemically stable plastics such as polypropylene (PP), polyvinyl chloride (PVC), or polyethylene (PE), plastic Raschig rings can withstand corrosion from most acids, alkalis, and organic solvents.

- Light Weight: Compared to ceramic or metal Raschig rings, plastic Raschig rings are lighter due to the lower density of plastic materials, making them easier to handle and install, and reducing the overall load on the packed column.

- Structural Stability: Plastic Raschig rings have good mechanical strength, allowing them to withstand physical pressure without deformation or breaking, making them suitable for long-term use.

- High Specific Surface Area: The cylindrical structure of plastic Raschig rings provides a large specific surface area, which helps enhance gas-liquid contact and improve mass transfer efficiency.

3. Advantages

- Low Pressure Drop: The structural design of plastic Raschig rings allows for smooth flow of gas and liquid within the packing layer, reducing pressure in the system and improving operational efficiency.

- Good Gas-Liquid Distribution: The cylindrical design of plastic Raschig rings ensures good distribution of gas and liquid, facilitating uniform mass transfer between the two phases.

- Cost-Effective: Plastic materials are relatively inexpensive, and due to their durability and low maintenance requirements, plastic Raschig rings offer an economical and efficient packing solution.

- Easy Installation and Replacement: Due to their lightweight and simple shape, plastic Raschig rings are very easy to install and replace in packed columns, saving time and labor costs during installation.

4. Applications

- Gas Absorption: Plastic Raschig rings are widely used in the chemical industry for gas absorption processes, such as the absorption of carbon dioxide, hydrogen sulfide, ammonia, and other gases.

- Distillation: In various distillation columns, plastic Raschig rings serve as packing material to enhance mass transfer efficiency during distillation processes.

- Degassing and Dehydration: Plastic Raschig rings are commonly used in processes that remove gases or water from liquids.

- Environmental Equipment: In waste gas treatment equipment, wastewater treatment columns, and similar applications, plastic Raschig rings act as packing to facilitate the separation and treatment of pollutants.

-

商品Q&A