-

商品資訊

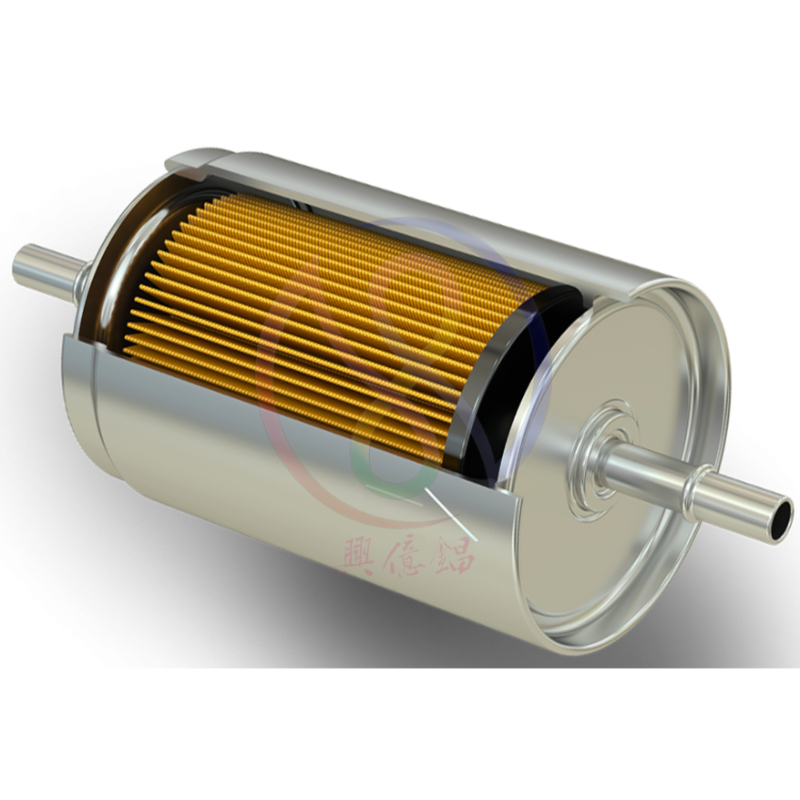

Oil Filters are devices designed to remove impurities and contaminants from lubricating oil, fuel, or other liquids. They are primarily used in automotive engines, industrial machinery, and various equipment to ensure the cleanliness and proper operation of oil systems.

Main Uses

-

Lubrication System Filtration:

- Removing Contaminants: Oil filters remove solid particles, metal shavings, and dirt from the oil in the lubrication system, preventing these impurities from causing wear on the engine or mechanical components.

- Extending Lifespan: By keeping the lubricating oil clean, oil filters help extend the lifespan of the engine or machinery and reduce maintenance frequency.

-

Fuel Filtration:

- Removing Pollutants: In fuel systems, oil filters remove particles and moisture from the fuel, preventing these contaminants from negatively impacting the fuel injection system and combustion process.

- Improving Fuel Efficiency: Clean fuel enhances combustion efficiency, improving engine performance and fuel economy.

-

Liquid Filtration:

- Broad Applications: In addition to lubricating oil and fuel, oil filters can be used to filter other industrial liquids, such as hydraulic oil or coolant, protecting the system's normal operation.

Advantages

-

System Protection:

- Prevents Wear: By filtering out contaminants, oil filters effectively protect engine or mechanical components, reducing wear and potential damage.

-

Performance Improvement:

- Stable Operation: Clean oil helps maintain stable operation and enhances the overall performance and efficiency of the system.

-

Reduced Maintenance Costs:

- Extended Replacement Intervals: Keeping the oil clean can extend the replacement intervals for both the filter and the oil, reducing maintenance costs.

-

Efficient Filtration:

- Multi-Stage Filtering: Many oil filters feature multi-stage filtration designs that efficiently remove various contaminants, ensuring high-quality oil.

-

Lubrication System Filtration:

-

商品Q&A